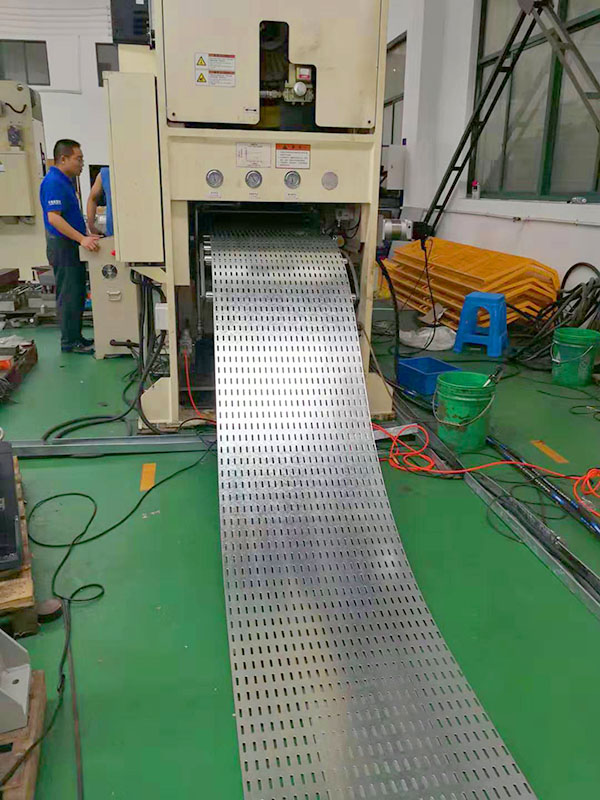

Sihua Cable Tray Roll Kugadzira Machine

Cable tray roll forming muchina (unonziwo cable ladder roll forming machine) unokwanisa kugadzira masaizi akasiyana ematireyi etambo kuburikidza nekutsiva punching molds. Matareyi etambo anogadzirwa neiyi roll yekugadzira muchina mutsara anoshandiswa zvakanyanya mumafekitori nezvimwe zvivakwa. Nekuda kwekusimba kwavo kwechokwadi. Cable tray roll yekugadzira muchina une decoiler (uncoiler), muchina wekusiya (lever), servo yekudyisa mudziyo, punching system, yekumberi yekucheka mudziyo, inotungamira mudziyo, roll yaimbova, yekumashure yekutwasanudza mudziyo uye inopera tafura.

Tine ruzivo rwakazara uye rwakakosha, tinogona kugadzirisa tambo tirayi roll yekugadzira michina kana tambo tirayi roll kugadzira mitsara yekugadzira zvinoenderana nevatengi "profile kudhirowa uye zvakatemwa.

| Zita | Units | Quantity | |

| Decoiler | Set | 1 | |

| Main Machine | Lever, Feeder, | Set | 1 |

| kugadzira muchina | Set | 1 | |

| Cutting Equipment | Set | 1 | |

| Hydraulic system | Set | 1 | |

| Electric control system | Set | 1 | |

| Packing table | Set | 1 | |

1. Italian tekinoroji German quality roll kugadzira muchina.

2. High speed high precision roll yekugadzira muchina weprofile yako yakanaka.

3. Mhando iyi yemuchina ine unhu hwakanakisisa uye mutengo wakanakisisa. Iine kuyerwa kwakarurama uye kushanda kuri nyore.

4. Tinogona kugadzira uye kugadzira iyo yakakosha mhando muchina zvinoenderana nezvinodiwa nevatengi uye isu tinogona kupa hunyanzvi hwekutungamira, kugadzira, kuisirwa, kugadzirisa uye kugadzirisa basa kune vese vatengi.

5. Chigadzirwa chedu chakatengeswa kumatunhu akawanda uye chakakunda mukurumbira wepamusoro nekuda kwehupamhi hwepamusoro uye mutengo unokosha.

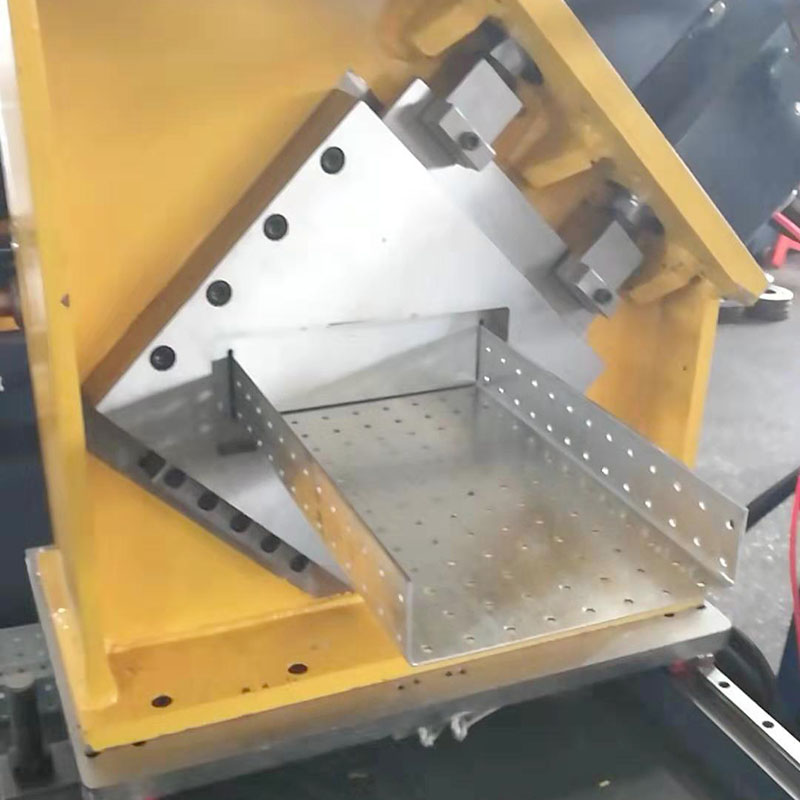

Iyo perforated Cable Tray Roll Forming Machine ndeye duplex uye yakakwira dhizaini yekugadzira tambo yekugadzira C chikamu chimiro chine maburi maburi ekutsigira waya yemagetsi mukutengesa uye maindasitiri kuvaka. Iyo tambo tireyi iyo yakagadzirwa neCable Tray Roll Forming Machine inowanzo gadzirwa kubva yepakati geji simbi ukobvu kubva 0.8 ~ 2.0mm.

Iyo perforated Cable Tray Roll Forming Machine yakabudirira kusanganisa hydraulic punching mudziyo kana high speed press muchina wemaburi emwaranzi patambo yetambo. Zvakare, iyo telescope shaft inowanikwa kukurumidza kuchinja saizi pasina shanduko yemutero. Pre-chekwa kana post cut inogona zvese zvakashongedzerwa kuchekwa kwapera chigadzirwa.

Yese Cable Tray Roll Forming Machine inosanganisira iyo Decoiler, Gaidhi mudziyo, Straighten rollers, Main Roll Forming Machine, Hydraulic system, Iyo PLC control system uye Ran-out matafura. Yedu roll yekugadzira muchina wakashongedzerwa necomputer control system. Iwe unongoda kuronga mukombuta chidimbu uye urefu hwaunoda, ipapo mupumburu wekugadzira muchina unougadzira otomatiki. Muchina uyu uri nyore kushanda, uye unoshanda zvakatsiga.

| Yakakodzera Plate Material | |

| Material - ukobvu | 0.8-2.5mm |

| Raw material | Galvanized simbi uye dema simbi mapepa |

| Kushanda Speed | 15mita / min |

| Kugadzira Matanho | 8zviteshi |

| Zvinhu zveRoller | cr12mov |

| Zvinhu zveShaft | 45 # Yepamusoro Simbi (Diameter: * 90mm), yekunatsa kwemafuta |

| Driven system | gear box drive, shafts dhayamita 70mm |

| Main Power ine reducer | 22KW SIEMENS |

| Kucheka | Hydraulic Kucheka |

| Zvinhu zveKucheka mashizha | SKD11 (JAPAN) |

| Hydraulic Station Power | 11KW SIEMENS |

| Muchina wese unodzorwa neindasitiri komputa-PLC | |

| PLC--Mitsubishi Japan | |

| Kubata Sikirini-KINCO | |

| Zvikamu zvemagetsi--Schneider | |

| Gadzirisa hurefu nemamotor uye njanji, inodzorwa nePLC | |

Mufananidzo wetambo tray muchina