Ceiling T grid roll kugadzira muchina

Zita remuchina:

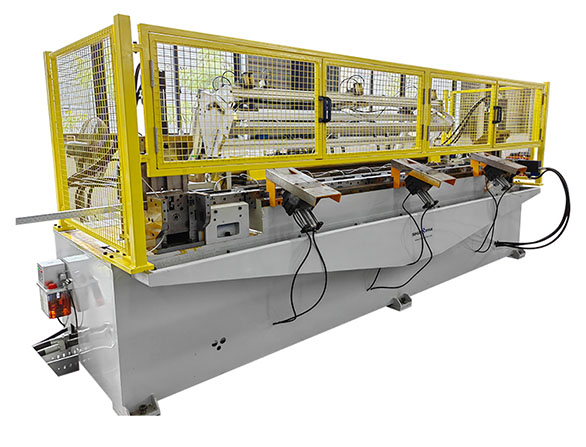

Otomatiki yakakwira yekumhanya-yakawanda Main tee grid roll yekugadzira muchina nekushandura imwe seti roller yekugadzira unit (COMBI).

Roller yekugadzira unit uchishandisa giya bhokisi

1.1. T-Bar yekugadzira mutsara inogona kutariswa nePLC. Kana iyo T-bar yekugadzira mutsara ine zvikanganiso, iyo PLC inowana zvikanganiso. Zviri nyore kuchengetedza vashandi.

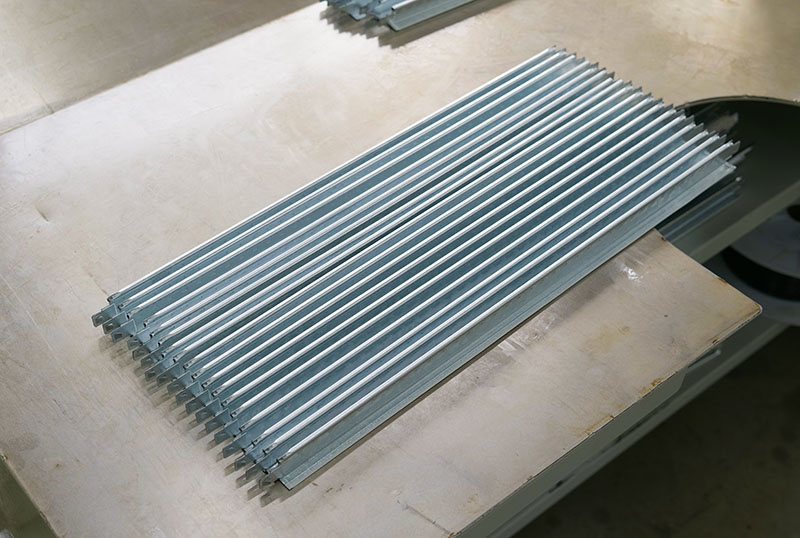

1.2. Iko kumhanya kweT-Bar Production iri mu0-60M/min. Cross t bar Avhareji yekumhanya ndeye 36m paminiti. Imwe miniti inogona kuburitsa 6PCS kureba 3660mm (12FT) chikuru-Muti 40PCS pakureba 1200(4FT).

1.3. Madimikira akasiyana Roller ekugadzira mayunitsi (6) anogona kutsiviwa mumaminitsi makumi matatu, 24X32H yakatarwa inogona kugadzirwa kana yakawedzera imwe seti roller yekugadzira mayuniti (6).

Kudhirowa kwechigadzirwa:

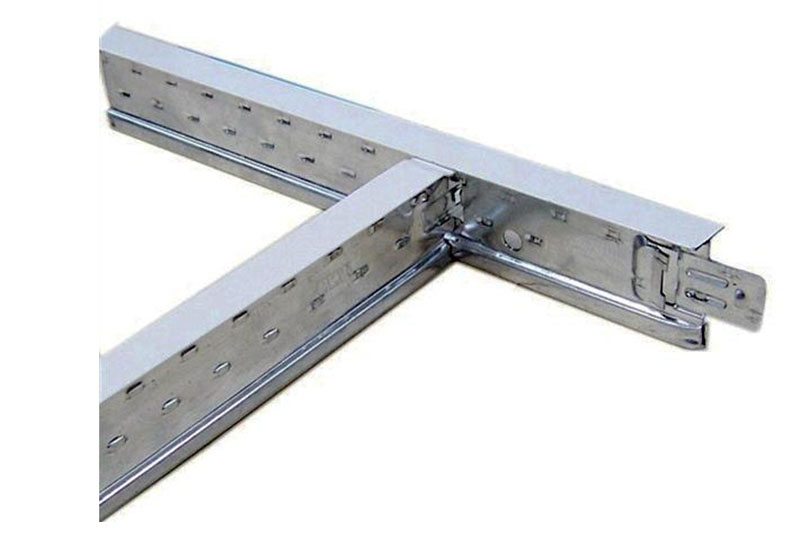

Main t bar mbiri 38h *24*3600mm/3700mm.

Muchinjiko t bar mbiri 38h*24*600/1200mm.

Isu tinogadzira muchina ita zvinoenderana nedhirowa yako yakasimbiswa.

1. Kaviri mota de-coiler (pendi simbi coil)

1.1. Kutakura simba:1500Kgs*2

1.2. Coil yakatarwa: OD 2,000 mm ID 508mm. Pendi simbi coil upamhi: 100 mm

1.3. Nekupa kutenderedza kuomesa coil

1.4. Inotyairwa nemota

1.5. Inotyairwa mota: 1.5kw

2. Kaviri mota de-coiler (galvanized simbi coil)

2.1. Kutakura simba:3000 Kgs*2

2.2. Coil yakatarwa: OD 1,500 mm. ID 508 mm. upamhi: 150 mm.

2.3. Neruoko kukwidibira mukati kuomesa coil.

2.4. Inotyairwa nemota

2.5. Inotyairwa mota: 1.5kw

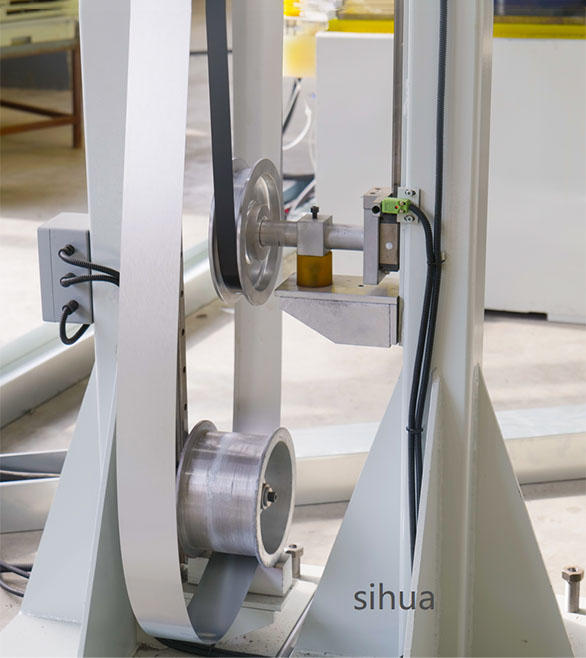

Iwo ma roller ekugadzira mayunitsi anoshanda mune yakakwirira-kumhanya, saka isu tinoda yekuchengetera unit kuchengetedza mota uye inoderedza uye kurebesa hupenyu hwavo.

Motokari simba ndeye 15KW, mhando ndeye ABB.

Muchina base zvinhu ndeye Q345-B simbi nekupisa kwese kurapwa kubvisa simba remukati kwehupenyu hurefu hwemuchina.

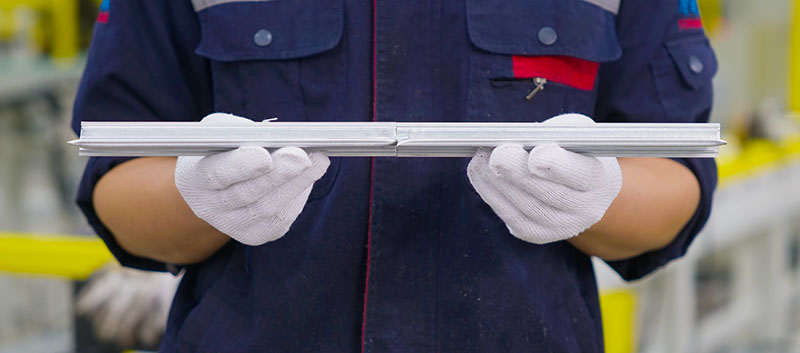

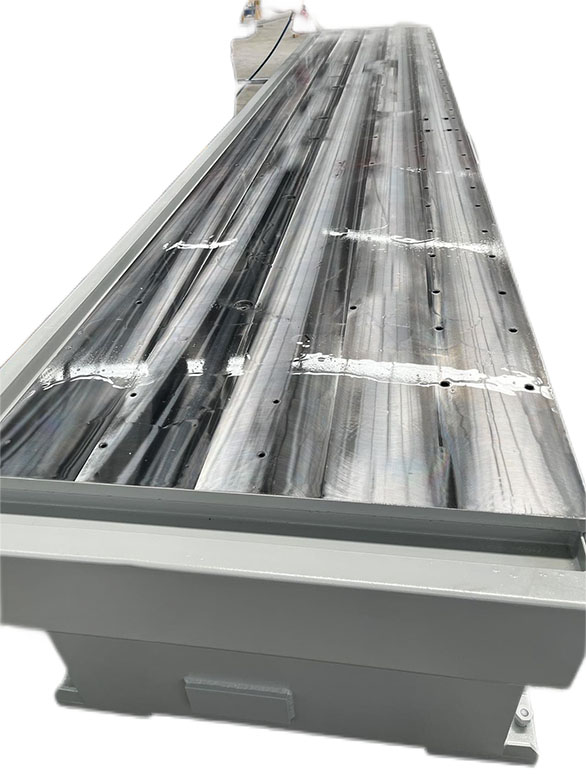

Iyo tafura yekushanda yemuchina inoshandisa yakakura CNC yakazara kugadzirisa kweyakanyanya nhanho, kushivirira kwakafuratira mukati me0.05mm, nzvimbo iri mukati me 0.02mm mune roller yekugadzira mayuniti kana yekuwana pini.

Roller forming units (COMBI) inogadziriswa pachigadziko chemuchina. COMBI inogona kutsiviwa zvichienderana neakasiyana t bar saizi.

Roll forming station 16+ 5 auxiliary rollers, Roller material is CR12MOV1(SKD11) Vacuum heat treatment 58-62 HRC.

Muchina wekugadzira roll unotora yakazara giya bhokisi chimiro kuti uwedzere hupenyu hwemuchina.

Iyo shaft musimboti dhayamita is∮40mm, zvinhu ndeye 40 CR nekudzima kurapwa kwekupisa.

Wall frame zvinhu: Q345 - B, CNC kugadzirisa, Kupisa kurapwa.

Kururamisa chigaro nhamba: 1 seti, kushandiswa kutwasanudza chimiro kubva kumusoro uye pasi, kumberi uye kumashure, kuruboshwe uye kurudyi.

Kugadzira mutsara kumhanya 0-80M/min. Kurumidza kana kunonoka kumhanya kunogona kuve otomatiki kudzora.

Punching die inoshandisa zvinhu zveSKD11 ine vacuum heat treatment, Kuoma kuri HRC 58–62.

Isa 6 zvimedu punching makomba anofa.

Yakachekwa-kureba 3600mm T-BAR inokwira maburi, Connector ne hydraulic punching, Robhoti inotakura Punched t bar kune stacking tafura.

Motokari simba: 15KW, Motokari mhando: ABB

Pombi kushanda kumanikidza: 140 kg Hydraulic kuyerera: 65L Brand is Rexroth (German)

Masilinda emafuta, huwandu: 9 zvidimbu

Accumulator:25L Mucherechedzo: OLAER (French)

Pressure sensor, IFM (German) iyo electromagnetic valve: Rexroth (German)

Filtration brand ndiParker (USA) 10.7, oiri inotonhodzwa nemvura kana nemhepo (sezvazvinoita).

PLC mhando: MITSUBISHI (JAPAN).

Shear controller:Italian (SIHUA).

Frequency inverter simba:15 KW mhando: YASKAWA(Japan)

Relay uye breaker brand: Schneider.

Man-muchina interface (yekubata skrini) mhando: KINCO, saizi 10.4 ".

Kabati yemagetsi, yakabatana newaya yekunze neplug inokurumidza.